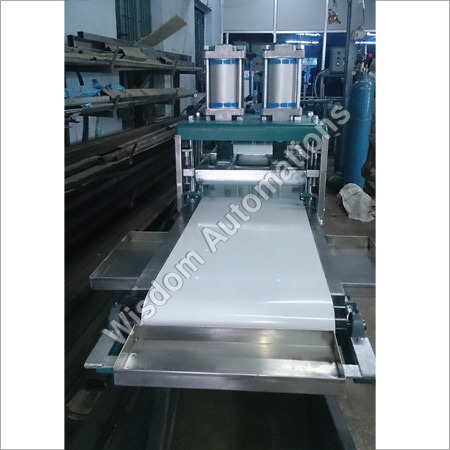

Leveraging on sophisticated tools and technology, we have been offering sturdy and high tech range of boli pressing machine. We have been offering durable as well as technically advanced array in different models to suit the exact needs of the clients. Our solutions are designed from the abrasion proof and robust raw materials to add long lasting life to the offered products. We provide the collection in customized designs also to fulfill the exact preferences of the patrons. Boli Pressing Machine, offered by us, is designed with automatic as well as manual operations and functions that ensure maximum efficacy. We design the collection with low maintenance and rust proof designs to make sure to provide the sturdy collection to the clients. Our range is developed in different models and designs with varied features to fulfill the exact needs of the clients.

Model No.: BMM - 2000

Specifications:

Conveyor : PU Food Grade

Pieces per pressing : 4 Pieces @ 5'' Size

Piece Thickness : Adjustable

Motor : 0.5 HP, 3 Ph

Power : 1 HP, 3 Ph

Operation : Electrical and Pneumatic

Control Panel with PLC, VFD to vary the Conveyor speed & Timer to set for auto stop.

Efficient Boli Production for Commercial UseDesigned for high-volume operations, this Boli Pressing Machine delivers up to 500 bolis per hour, accommodating diameters ranging from 4 to 8 inches. Its semi-automatic, floor-mounted design enables a single operator to manage the entire process with minimal effort. The sturdy, powder-coated mild steel body ensures longevity and reliable performance for various food businesses.

Safety and Simplicity CombinedWith an operator-friendly interface featuring push button controls and an emergency stop button, the Boli Pressing Machine prioritizes safety and simplicity without compromising productivity. Its low noise operation and easy-to-move transportation wheels make it a practical choice for busy kitchens and production facilities.

Easy Maintenance and Low DowntimeBuilt for longevity and consistent results, this machine requires minimal maintenance. The rapid cool-down period (less than 10 minutes) minimizes wait times between production cycles, while food-grade stainless steel plates ensure hygiene and simple cleaning. Ideal for distributors, exporters, manufacturers, and suppliers demanding efficiency and reliability.

FAQs of Boli Pressing Machine:

Q: How does the Boli Pressing Machine ensure uniform thickness for each boli?

A: The machine features an adjustable thickness setting, allowing users to select their desired consistency. This ensures each boli comes out with a uniform thickness, improving product quality and meeting diverse customer preferences.

Q: What is the process for operating the Boli Pressing Machine?

A: To operate, simply feed wheat flour dough manually onto the pressing plate, use the push button controls to start the pressing cycle, and the semi-automatic mechanism completes the rest. The machine requires only one operator and is designed for easy and safe operation.

Q: When should I perform maintenance on the Boli Pressing Machine?

A: The machine is built for low maintenance needs. Routine cleaning after daily use and regular checks of mechanical parts are recommended. Detailed maintenance intervals can be found in the manufacturers manual, but most users find standard preventative care sufficient for long-term operation.

Q: Where is the ideal place to install the Boli Pressing Machine?

A: Installation should be on a flat, sturdy flooring in a well-ventilated, food-preparation area. The machine is floor-mounted for stability and comes with wheels for convenient movement when needed, making it suitable for both commercial kitchens and food production units.

Q: What are the main benefits of using this Boli Pressing Machine?

A: Key benefits include high pressing efficiency (up to 4000 pieces per shift), consistent product thickness and diameter, low noise operation, quick cooldown time, and ease of mobility. Its user-friendly controls and safety features further enhance usability and productivity.

Q: How is safety maintained when using this machine?

A: Safety is prioritized through features like an emergency stop button, insulated electrical controls, and robust construction. Operators should follow safety guidelines provided in the manual to ensure optimal and secure usage.

Q: What features make this machine suitable for large-scale boli production?

A: With a production capacity of 500 boli per hour, adjustable thickness, easy operation, and low maintenance requirements, the machine is ideal for distributors, suppliers, and large kitchens seeking reliable, efficient, and uniform boli production.